What can you say about the approach to innovation at Ophtec?

First and foremost, what I believe we do differently compared to R&D departments at similar companies is that our origins are grounded on those of an eye surgeon, who was himself also an eye doctor and developer (Prof. Dr. Jan Worst). So, that connection to the surgeons themselves is really in our DNA. As part of this approach, our R&D engineers collaborate with doctors on a real personal level – they take a seat next to them and exchange ideas – then they start innovating together. For us, innovation is always a joint venture between a request from the market, a surgeon, or healthcare experts. And from that point forward, we get the input and make our plans.

Over time, with advances in technology, such as digital design, development and simulation software we have further digitalized that process. Think, for example, of quick sketching, rapid 3D prototyping, detailed eye models and adopting virtual reality. These are all ways to get the idea from the surgeon directly onto the table. Ultimately, experiencing something firsthand is always more valuable than a presentation. In short, we maintain that old school approach to innovation but try to incorporate all the technological advancements that we see nowadays into it.

Which technologies have emerged from this collaborative approach to innovation?

The Artisan product is perhaps the best example of this. This was really a novel innovation at the time of launch of Ophtec, and it still continues to perform well. Our original founder, Prof. Dr. Jan Worst, who was himself an eye doctor, came up with the idea to fixate the lens onto the iris of a patient some 40 years ago – a completely novel idea at the time. In that approach, he had an engineer (Harry Simons, who continues to work at Ophtec R&D department) next to him and he conversed with him. The basic dialogue was effectively grounded on: “I need an instrument or a lens that performs in this way, and looks like this.” By the following week, it was already in his hands and being tested. So, the innovations process was quite quick – without any hassles.

Our Artisan product was developed in that way, with a very quick development time that was just grounded on taking an idea into reality and implanting it into the patient’s eye – while ensuring patient safety. This laid the foundation for the iris-fixated products that would eventually become the Artiplus range. That collaborative approach has continued to be the foundation of how we do things at Ophtec.

While growing substantially over the years, how have you managed to keep the R&D person connected to the surgeons in the innovation process?

Practically, it relies on a lot of face time and connection on both a technical and personal level. Each doctor has their own approach. Some are very active – they’re big characters with big ideas – and you sometimes need to temper their expectations. Others are a little more cautious, and looking for more validation when implementing a new technology. So what we try to do is ensure that all of our R&D engineers also have different backgrounds, and personalities. We try to match them with ophthalmologists who have similar character traits.

In fact, the basis of what Prof. Dr. Worst did with his original instrument makers, is still what we do nowadays with our 10-12 R&D engineers. Interestingly, all of those people who were there at the beginning of Ophtec as instrument makers or technicians, are still with us today as R&D engineers. Some are on the verge of retirement and are passing on this approach and their collective knowledge to a new generation. We really have that great blend of generations in our company and long may it continue.

You’ve been in your role as COO at Ophtec for just over two years. Can you share a bit about your background before joining?

My background is in mechanical engineering. One of my first roles was at a company producing diesel-powered generators. As an engineer, I would look at what I was designing – and while I recognized that this was something that the world needed, I didn’t feel any interest for it. For me, if it’s your profession, you should want to care – you should want to make a difference. So that’s why I moved into MedTech. The notion that someone could see well again due to your product is one of the most motivating feelings you can have. So I took on a role as a production engineer in the contact lens industry. During that phase I started developing both products and optimizing production lines for contact lenses. One of the biggest achievements of my career at the time was supporting the joint development of a “smart contact lens,” which included an LCD screen to help patients with aniridia [a rare abnormality characterized by the partial or complete absence of the iris]. I tried to make products for every patient – there was nothing outside our scope, but not all would see commercial introduction, because the market was too small, or a product might not be economically viable. With this mindset, I moved into general management at that company, where I used a similar approach to create a framework where I challenged our team to ensure that each patient could have access to the right product at the right price, and make it economically viable for us.

So what’s happened after your move here?

I moved to Ophtec in January 2023 to literally go deeper into the eye. But the same core principle remains. Of course you can make products that are smarter, better and more streamlined, but the company as a whole needs to enable those ideas.

So what happened in recent years is that a lot of regulatory compliance issues has become tougher. The transition in the EU from the Medical Devices Directive (MDD) to the Medical Devices Regulation (MDR) [implemented in 2020] has had a vast impact. MDR requires much more clinical data for substantiation and is more restrictive when it comes to innovation. My main challenge in the last couple of years has been how to remain nimble, flexible & patient orientated, while being fully compliant.

Can you give an example of how you’ve overcome regulatory hurdles?

I think our revised approach to developing technical files is a good one. Traditionally, technical files have been very specific to a product, but you can also take a modular or matrix approach whereby you leave the possibilities for line extensions. It’s fundamentally about thinking about products as solutions rather than as an end point. So, for example: A lens is made from an optic; The lens itself is a polymer body; The way that the lens is applied to the eye is via an injector. You could of course make a technical file that covers all of those facets, but you could cut it up into the three applicable subjects too. In that way, if you subsequently were to change the material or extend the line, it would be much easier to do than documenting the entire process.

Using a modular or matrix approach makes it easier to move towards new products. If my engineers have more space to play in, they can iterate more quickly and make better products and move quicker on them. This modularity gives our R&D and regulatory teams the breathing space required to take things to market, while remaining compliant.

Are there other operational methods you have implemented to navigate the regulation?

When I joined the company, Ophtec had a traditional structure. Rather, than giving a majority voice to those with the most experience or seniority, we wanted to ensure that people with the right expertise (regardless of their role) were given a podium. We achieved this by flattening the technical side of our operations. This led us to implement a system with just two layers of functional hierarchy: directors and middle management. The technical teams with technology and operations operates at one hierarchical level. This means that those with the best ideas can vent them directly.

Furthermore, the middle management of operations is always run by multiple people to ensure that all angles are considered. This “multiple perspective principle” enables the best ideas and allows us to keep on moving forward and keep asking the best questions. As COO, I’m responsible for all Technology and Operations departments. One of my personal passions is creating novel products and staying close to the patient. Others in the team have their own passions too. When you combine all those passions, you get the best ideas and perspectives.

Building on that, how has the connection between R&D and commercial teams evolved over time?

During the time that I’ve been here, we’ve been more proactive in growing towards the commercial parts of the business. We see that the triangular connection between our technical and commercial teams and the eye surgeon is key. When these three parties work well together, it creates the best and most relevant products on today’s market. For example, if a customer has an issue with one of our products, not only can our account manager approach them, but our R&D engineer will join them too. That dynamic demonstrates that the issue is being taken seriously, but it also leads to solutions and new innovations.

What motivates you about Ophtec?

For me, what is central about how Ophtec operates is that we are all about partnerships with you, our surgeon partners. Working together is really in our DNA, whether in R&D, Operations, or Commercial. We are in this together and if you call us, you can be sure that you’ll get a person on the line. We are one phonecall away. I’d like to stress that some of the best ideas we have ever received came directly from surgeons. Real innovation comes from eccentric, highly creative people who break the mold, and we want to be in contact with them so that we push this sector forward together.

Have any of these technologies emerged from a closer connection to the marketplace?

We recently co-developed a product together with a surgeon. He had a great idea for selling one of our products as an active medical device that would perform an additional function when attached to the eye. During the development, we reached out to the commercial team, to make a calculation about whether this would be interesting to commercialize and see whether it would be beneficial for the patient. The conclusion was that it was interesting, but not in this exact form. We see that on the whole scope of new products that we are developing. Collaboration between the surgeon, technical, and commercial teams accelerates development and leads to great products.

What advice would you have for practices who are bringing new Ophtec technologies on stream at their practices? What are the best ways to communicate this to their patients?

Firstly, you should use the materials that you are given that explain the purpose of the product and the technical tidbits that go with it. We have wonderful digital learning environment featuring compendiums, technical explanations, and webinars to support surgeons in this. Furthermore, it’s good to talk to the clinical, technical people to get an understanding of what the product does. Then it is a matter of explaining that in simple terms towards the patient – after all they will listen to what they are told but are unlikely to understand the detail and jargon. Ultimately, it’s all about focusing on relatable benefits for them. For example, for Artiplus, I would summarize the benefits as follows: “you’ll get back the best vision you ever had. You’ll see small items, you’ll see at a distance – you’ll enjoy the perfect range of vision, all the time. You’ll be able to read small print, but also see into the distance.” Explaining real world applications helps patient satisfaction.

What are some of the challenges that you are facing in manufacturing and production and how are you overcoming them?

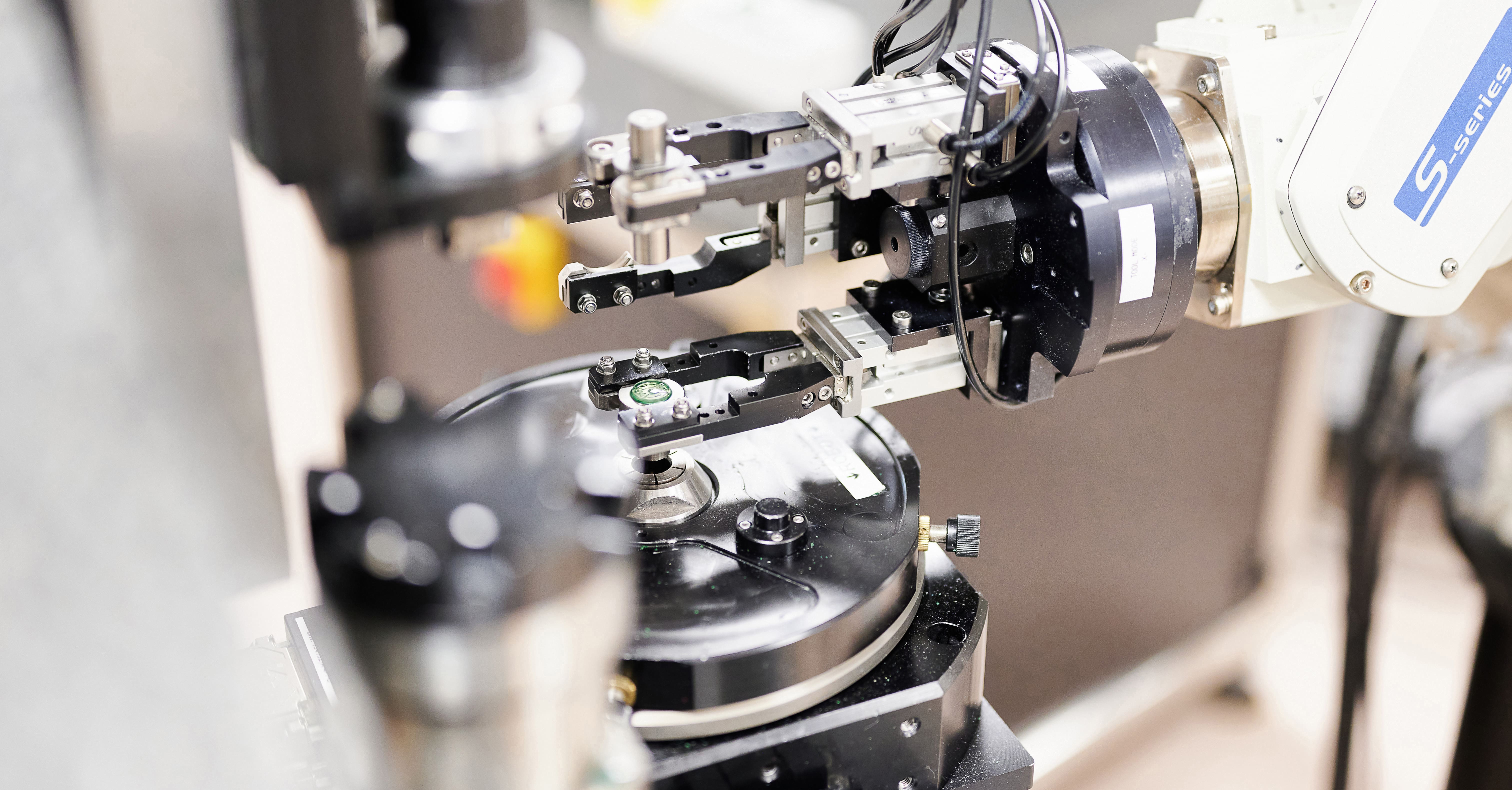

Our main challenge right now is that we make a wide scope of products, with different lens uses and parameters. So we need to be flexible, maintain quality, but do so at an economical price. We don’t have any single product that sells billions of units. Rather, we have quite a diverse portfolio of products So it is less about automation and more about mechanization – so making sure that everything that is labor intensive is either done by robot or cobot [one that works in conjunction with a human]. It’s about creating a hybrid between mechanizing the process, while ensuring that our experienced and artisanal operators are in charge of what really matters, premium product quality. So our challenge is finding that optimal balance.

As such, we have a highly diverse product portfolio that is difficult to standardize, so you need to be able to manage that in your operations and distribution. That’s why we are investing in our operations and production to take that next step in manufacturing towards operating a “smart manufacturing” process.

Even after 40 years, the fundamental foundations at Ophtec remain the same. We’re in this together to ultimately benefit your patients!

Where do you see new market opportunities and where are you expanding?

We currently have two basic pillars for treatment: cataracts and refractive markets. Our third pillar of development will be offering highly specialized trauma lenses. We have made trauma lenses in the past , but had to phase out their production due to the MDR regulation. However, having had some time under this regulatory framework and with the introduction of our modular approach, we now see some opportunities to revive them, and also add to that portfolio at the same time.. These products can also include active medical devices to take things to the next level. It could range from helping glaucoma patients control and monitor their eye pressures , those who have suffered traumatic eye damage through accidents or genetic deficiencies in the eye.

The point about trauma products is that these issues are not as widespread as cataracts – these are small and specialized markets that subsequently are not catered to any more. But those patients are still around and still suffering. Beyond lenses, we are also trying to focus on the ecosystem as a whole. A good surgery requires good instruments and injectors – so beyond our lenses there are other tools required to succeed. That’s something that we want to venture into, in order to get that full range. For this, we will collaborate with partners, but always stay true to Ophtec’s premium quality standards.

%20magazine/2024/Blog%20-%20R%26D%20Tim_800x800-1.jpg)

%20magazine/2024/OTR%202024%20-%20Sjoerd%20blog_header_800x450.jpg)